Safety self-audits are a useful tool for an organization in building and maintaining a safety culture. Just like a safety committee, safety self-audits are a communication process through which information can be gathered, analyzed and acted upon.

What is a safety self-audit?

It is a process through which work areas are examined and assessed to determine if policies and procedures are being followed. It provides a great opportunity to recognize safe work environments. The process also helps identify unsafe working conditions, damaged equipment, improperly stored materials and items, and conditions that could lead the injury.

What are the benefits of conducting safety self-audits?

- Safety self-audits help guard against complacency. Regular auditing can help prevent unsafe conditions and reinforce the importance of a safe work environment.

- If conducted by teams of employees from various departments, this process can lead to a better understanding of the work environments in different departments.

- Safety self-audits also demonstrate the organization’s commitment to providing a safe work environment and the empowerment of employees regarding safety.

- Any issues identified in a facility can be shared through the safety committee, and possibly identify similar unaddressed issues in other facilities and/or departments.

- Observations made during audits may help identify the need for either additional or refresher safety training.

Safety self-audits and safety committees are two key components to establishing a strong culture of safety in any organization.

If your organization would like to explore safety self-audits, please contact your IMWCA safety and risk improvement advisor. They can assist you with implementing this program.

What Personal Protective Equipment is the Employer Responsible to Provide?

A common question we get from members is: What personal protective equipment (PPE) do I have to provide the employees, and what are they responsible for? This article will provide a basic review of what is required of the employer and when it’s needed.

First, to determine what PPE is needed, the employer with the employees must conduct an exposure review of the tasks that are performed by the employees to determine what risks are present. For example, employees using a chainsaw have exposure to cuts from the chain, loud noise, flying wood bits, overhead branches and crush hazards from rolling or dropping branches. Based on this review, the employee must be outfitted with a hard hat, hearing protection suitable for the noise level, chainsaw chaps, eye and face protection and safety-toed boots.

IMWCA has model PPE policies and other policies on our website that can assist members in determining what they need for PPE based on the exposure. You should perform these reviews annually to ensure you update your PPE with any changes in operations and new exposures.

For a more in-depth analysis of PPE requirements, members can review OSHA standards at 1910 Subpart I – Personal Protective Equipment 1910.132 through 1910.140 for General Industry and 1926 Subpart E- Personal Protective and Life Saving Equipment for Construction, 1926.95 through 1926.107.

There are two items that employers can require employees to purchase themselves. Safety-toed boots and prescription safety glasses are meant for use by only one person and considered “personal wear.” Employers must make sure that any of these items meet the ANSI standards for exposure. Many employers have a footwear and eyeglass allowance to help the employee cover these expenses and to also make sure they buy the right quality of PPE.

If you need any guidance with PPE questions please reach out to your IMWCA safety and risk improvement adviser for assistance or you can contact OSHA consultation for more information.

Upcoming Virtual Round Table:

- August 12

Conducting Effective Safety Meetings

Workers’ Compensation Virtual Round Table

Gain valuable knowledge and real-world solutions for handling workers’ compensation issues in our quarterly virtual round tables. Each session kicks off at 9:30 a.m. with a 15-20 minute presentation, followed by an open discussion where you can ask questions and exchange ideas.

We encourage participants to submit questions when registering to make the discussion even more relevant. These round tables are also a perfect fit for your monthly safety meetings, providing valuable training for your team. All sessions will be recorded. Don’t miss this opportunity to stay informed and improve workplace safety!

Outdoor workers face a higher risk of skin cancer, the most common cancer in the U.S., and employers have a responsibility to help protect them. UPF-rated clothing offers a safer, longer-lasting alternative to sunscreen, helping reduce UV exposure on the job.

Upcoming Webinars:

- August 5

- August 14

- August 19

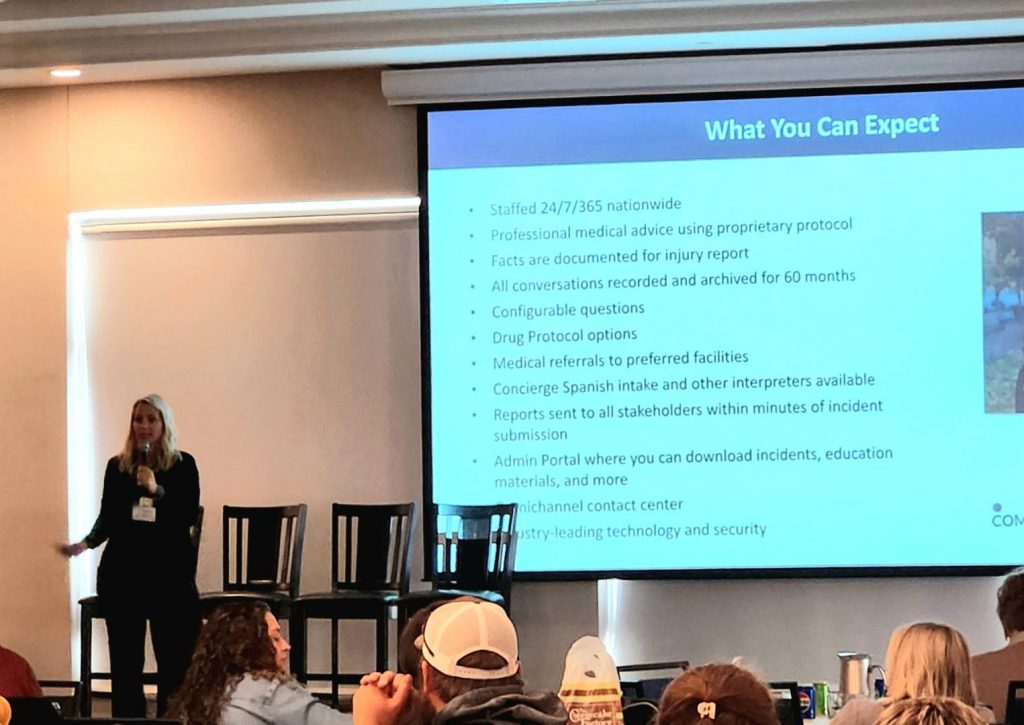

Webinar: Optimizing Injury Reporting & Triage for Better Outcomes

Join us for this interactive webinar as we walk through the Company Nurse process and how the Omni Contact Center makes injury reporting simple and efficient. You’ll learn how employees can report injuries using tools like the Digital Assistant and QR Code, and how the Admin Portal gives members direct access to reporting and case management features.

We’ll also share real results—like trends in lag time, self-care recommendations, and key injury metrics—and invite your questions throughout the session. Whether you’re new to the system or looking to improve your injury management approach, this is a chance to learn, ask questions, and get practical tips from the experts.